Home / Light guide plates

Light guide plates Lightplex

Light guide plates; efficient and uniform lighting with Lightplex®

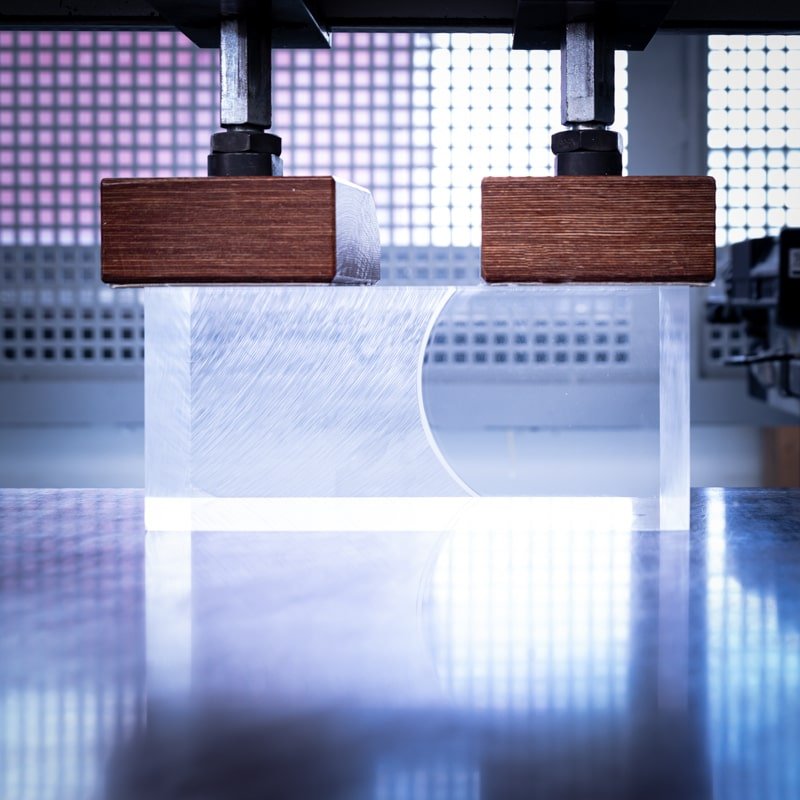

Light guide plates, or LGP, are high-output plates that ensure a beautiful, even light distribution. You can therefore safely think of the light guide plate as a light diffuser. The light source consists of LED lightning in the form of a strip. Depending on your preferences and the size, the LED strip can be attached to one side of the light guide plate or multiple sides.

Applications

Light guide plates offer numerous possibilities for various applications, including signage, billboards, urban farming, displays, and ceiling, wall and even floor lightning. Due to its water-resistant properties, Lightplex® is also suitable for humid environments. In short, the possibilities are endless. You can also use Lightplex® as a light diffuser: with the light guide plate, you can create diffused light in any desired location. For special effects, Lightplex® can also be combined with light tube material.

Revolutionary technology

Thanks to the unique technology behind Lighplex®, the light beams from the LED lightning are uniformly distributed. The characteristic dot pattern pattern plays a key role in this. These dots guide the light out of the light guide plate, resulting in a very high light output. With Lightplex®, you achieve diffused light, making it an excellent light diffuser plate.

Lightplex® is the most uniform of all LGP techniques, especially for larger sizes. The material does not discolor and is durable. Since the plate is clear is emits the same color as the incoming LEDs, making it particularly suitable for RGB LEDs.

Lifespan, quality and sustainability of Lightplex®

Lightplex® is made from high-quality acrylic and meets stringent standards, ensuring exceptional quality. Due to its consistently excellent performance, Lightplex® is a popular choice in various demanding environments, especially where diffused light is desired. Moreover, the lifespan of the light guide plate often surpasses that of the LED lighting itself.

To prevent these plates from ending up in the waste bin, Pyrasied offers a recycling program where the light plates can be returned for recycling.

Custom-made light plates

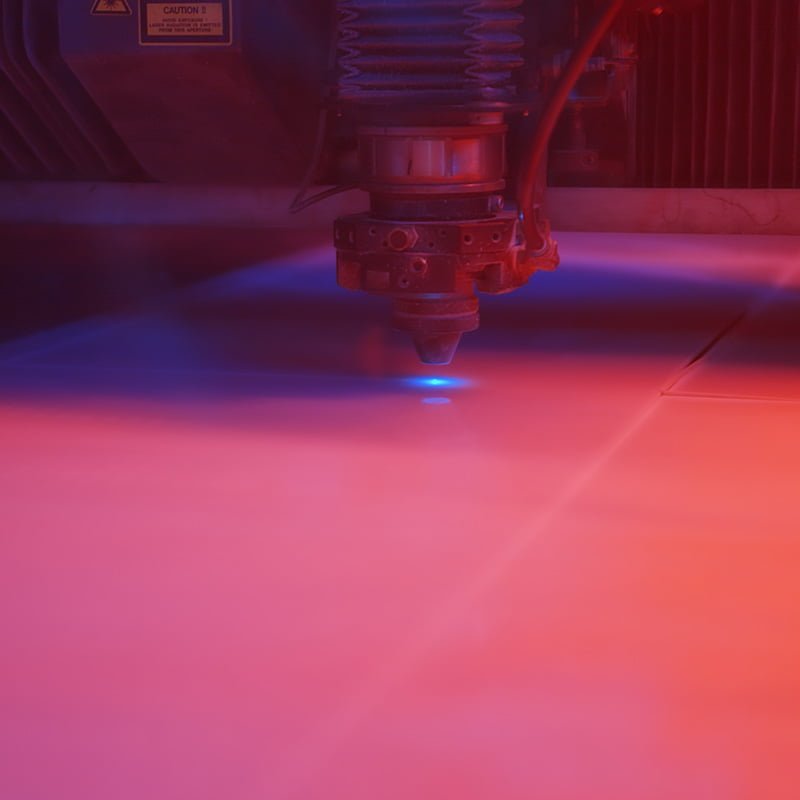

Lightplex® is always made according to your specifications. Before producing a light guide plate, it must be determined on which sides the LED lighting will be placed, as this affects the choice of laser techniques on the plates.

The maximum plate size 3000 x 1500 mm. The light plates can be manufactured in thickness ranging form 4 to 15 mm, depending on your requirements and application. Need diffused light? Then the light diffuser plates from Lightplex® are an excellent option.

Larger designs

Do you need a larger light guide plate? No problem. With larger sources on both sides, the plates with polished edges can be placed together to create a larger light guide plate. We recommend testing this configuration in advance.

Measurement is key

Exclusive assistance for batch production

Are you involved in a project that requires the development of a batch light guide plates and unsure about the suitability of Lightplex material? Pyrasied specializes in in batch production and offers additional support for various projects.

We routinely conduct outgoing inspections with a test setup for serial productions. This ensures that you always receive quality products that meet your specifications. Our experts can work with you to measure all values and tolerances, allowing you to get the most out of Lightplex. Additionally, they are skilled in documenting measurement methods and performing quality checks, specifically aimed at maintaining consistency in values and ensuring that the delivered products meet your standards.

Specifications of Light Guide Plates

Lightplex meets the fire standard EN 13501-1, class E, and is water-resistant, making it suitable for both indoor and outdoor use. The light difusser material remains clear in color, does not yellow, is UV-resistant and 100% recyclable. The Lightplex guide plate is available in sizes up to 3000 x 2000 mm and in thickness ranging from 4 to 15 mm.

Get in touch with the Pyrasied team directly

We can discuss projects with you, provide technical advice, send a sample, or process the sheet material for you—whatever you need.

Get in touch with the Pyrasied directly

op je telefoon

Bewaar mijn gegevens