Home / Services / Plastic processing / Bonding

Bonding

We know bonding through and through

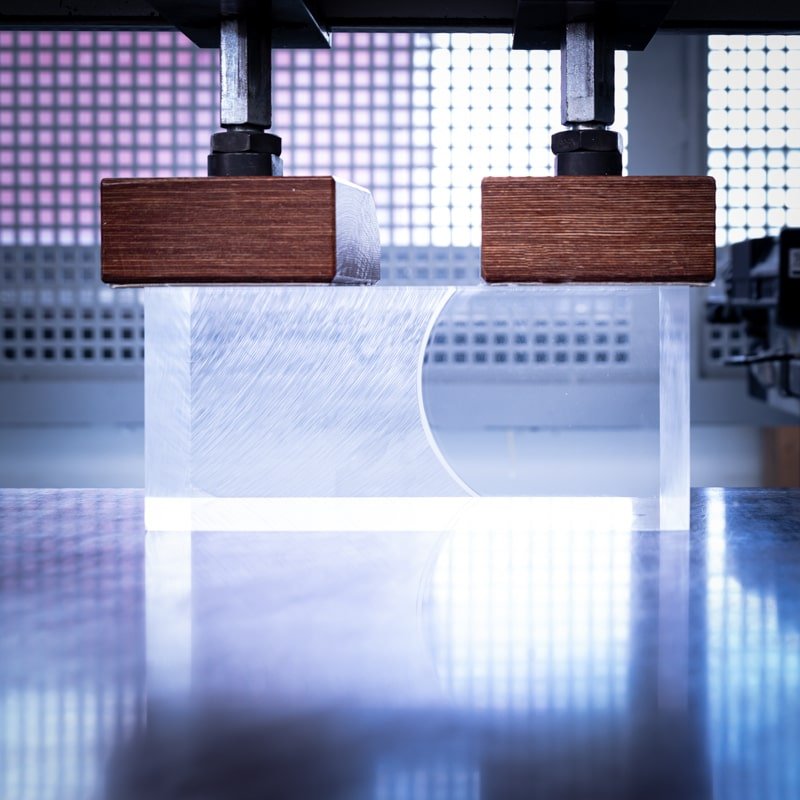

At Pyrasied, we bond acrylic, polycarbonate, PETG and many other materials. Shape is not an issue: whether it’s a block, tube, rod or sheet, we can bond it durably for you. A mark of our quality is that we make sure the bonds are free of air bubbles. At Pyrasied we can carry out mitre bonding, end-to-end bonding and surface bonding of multiple sheets. Each kind of bonding requires a different type of post-processing, except for mitre bonding, for which post processing is not necessary.

Pyrasied adhesive quality

Pyrasied has almost half a century’s experience in fabricating plastics. Our main speciality is bonding pieces such as display cases, cabinets and dust covers to a museum-level quality. This means the bond is completely seamless and the edges are perfectly finished. No sign of adhesive residue remains and the bond is so good that the different plates seem to melt into each other, so that the separate components become one.

Professional expertise

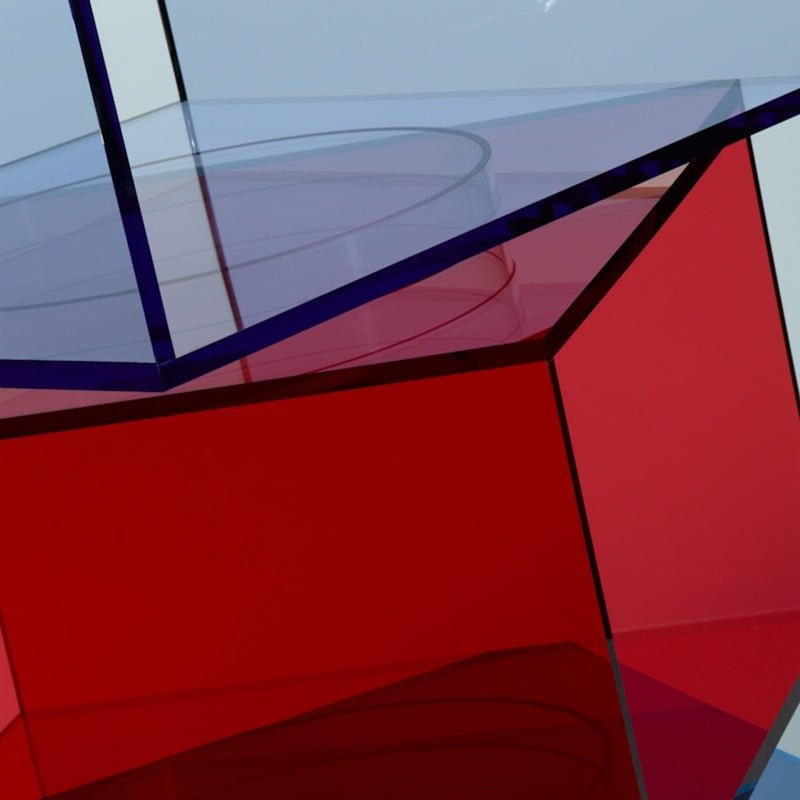

We are familiar with every aspect of bonding plastic. Whether a single-component mitre bond or two-component end-to-end bond is needed, anything is possible. Museum-level quality is our standard. If you prefer a visible colour gradient between two plates, that’s no problem. Surface bonding multiple plates is one of our specialities, enabling us to create an appealing colour gradient by bonding several plates together.

End-to-end bonding

Another option for joining materials is end-to-end bonding. With end-to-end bonding, the ends remain straight and are joined together using UV adhesive. During bonding, the adhesive flows into the seam. It is then necessary to mill and polish the material to produce a smooth result. End-to-end bonding is recommended for large, heavy objects constructed using thick plates that need to be particularly strong, such as large cabinets, furniture or objects for interior applications. End-to-end bonding is the strongest technique available.

Extremely strong joints

The bonds not only have to look good, they have to be functional too. Strength and durability are key when bonding materials. Pyrasied makes sure that the bonds are strong and long-lasting so that your bonded objects stay beautiful and suitable for long-term use.

Mitre bonding

Edges can be mitre bonded or end-to-end bonded. With mitre bonding, the edges are milled to 45 degrees and melted together with a UV bond. The adhesive flows into the seam and no post-processing is required. Mitre bonding is therefore cheaper than end-to-end bonding. Mitre bonding is primarily chosen for display cases, dust covers, protective covers, check-out counters and cabinets. If transparent materials are being used, mitre bonding is the most aesthetically pleasing solution.

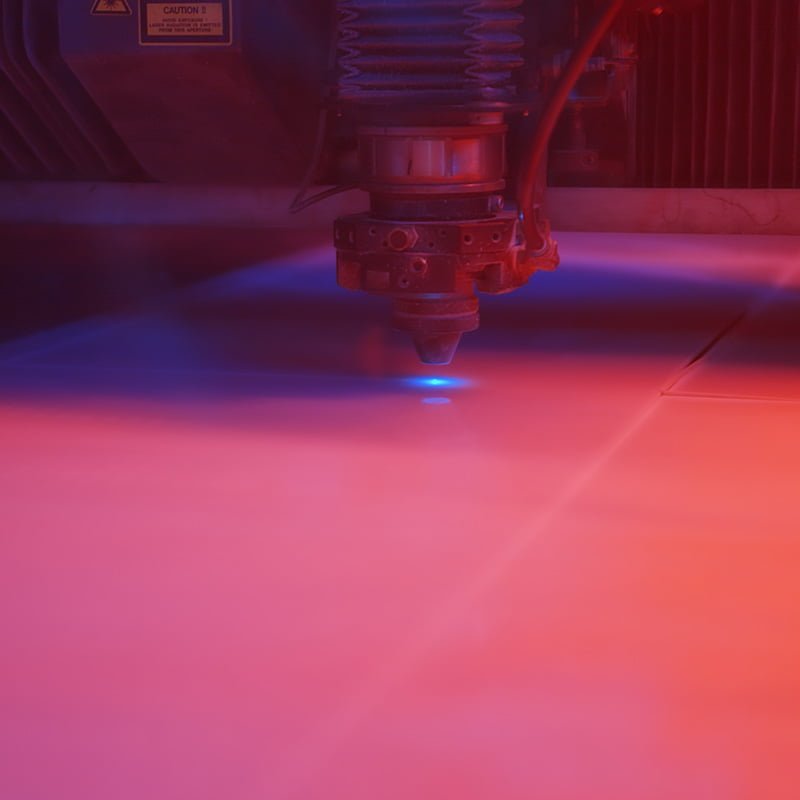

Introducing our machinery

In our bonding work, Pyrasied generally uses 1K bonding (UV bonding) for sheets with a thickness of up to 15 mm. This produces strong and clear bonds. For plates thicker than 15 mm, we switch to 2K bonding, for which we use Acrylic 190 2-component adhesive to create durable and robust acrylic bonds.

With our years of experience and advanced techniques, we create flawless bonds that meet the highest standards. Your projects are in safe hands with us.

Kies uit onze andere materiaalbewerkingen

Wij staan voor je klaar om je verder te helpen.

Get in touch with the Pyrasied team directly

op je telefoon

Bewaar mijn gegevens