Home / Services / Plastic processing / Bending

Bending

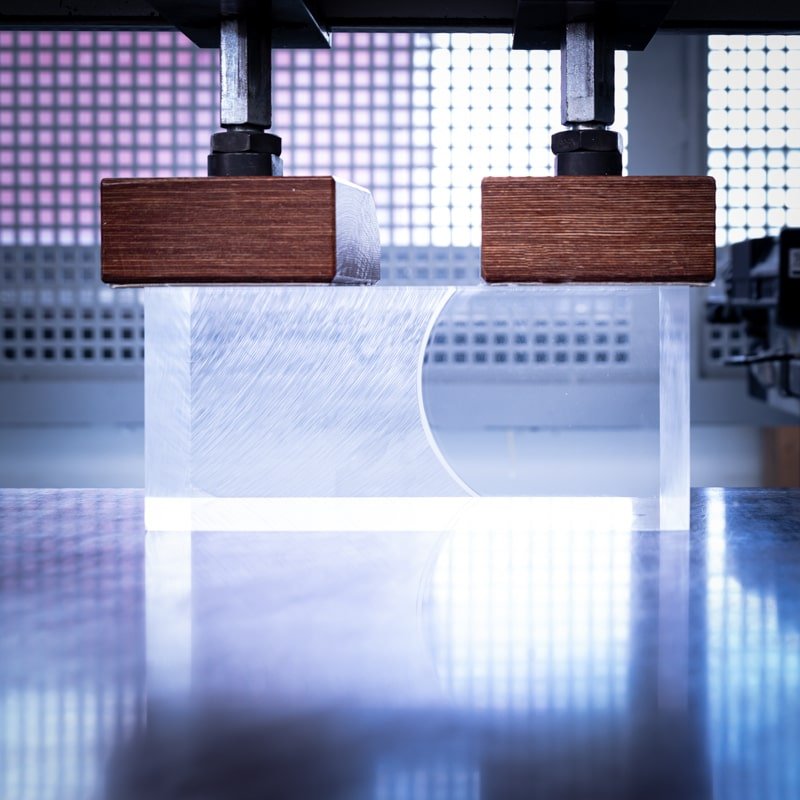

Cold or hot bending

We have various ovens and heaters for bending a wide range of materials. There is a distinction between cold and hot bending. Materials that can be bent while cold include acrylic and polycarbonate. This process is also known as ‘pressing’. We can perform this for you with a minimum radius of 230 times the thickness of the sheet for cast acrylic. For extruded acrylic, the minimum radius is 300 times the thickness of the sheet, and for polycarbonate, it is 100 times the thickness of the sheet.

A smaller radius is also possible, but we recommend hot bending for this purpose. This method allows you to bend without creating stress, and Pyrasied uses special ovens and heaters for this process. Hot bending is possible with acrylic, polycarbonate and PETG. We can bend acrylic, polycarbonate and PETG along one or two axes.

Virtually anything is possible

We have several ovens and heaters at our disposal, allowing us to perform line bending and oven bending – also known as drape forming – for you. Our heaters are two metres long, and our ovens are generously sized with an area of 3 x 3 metres and a height of over one metre. This means Pyrasied can do a lot of things for you. If you need multidimensional bending, that’s no problem either. Feel free to contact us if you have specific bending needs.

Extended lifespan

Pyrasied has more than 40 years’ experience in bending plastics. You can imagine that we have accumulated a lot of expertise in that time. For example, because we know exactly when and for how long the material has to be heated and cooled down, we can even extend its lifespan.

Custom bending

At Pyrasied, we can bend material beyond the minimum radius if required. We do this with moulds that we design and make ourselves. Whether the designs are complex or the shapes unique, our custom solutions guarantee a precise and lasting bend. Afterwards, you will be given the mould as part of your delivery of plastic panels. That way, if you need exactly the same product in future, it can be made using the same mould.

Top-quality finishing

Our professionals make sure the bent sheets are perfectly finished, with smooth edges and precisely shaped contours. After all, the finish is crucial to the final look of your project. It will come as no surprise that we pay such close attention to detail.

Can all plastics be bent?

Thermoplastic plastics such as acrylic, polycarbonate and PETG can all be bent. By contrast, the bending of thermosetting polymers such as Solid Surface material is not so straightforward.

Kies uit onze andere materiaalbewerkingen

Wij staan voor je klaar om je verder te helpen.

Get in touch with the Pyrasied team directly

op je telefoon

Bewaar mijn gegevens